|

Sheet metal perforation machine is a kind of equipment specially used to punch holes on the surface of metal coil into the hole shape and diameter required by customers. In modern manufacturing, perforated metal machine plays an indispensable role and is widely used in many fields such as construction, automobiles, electronics, and home appliances. With the continuous advancement of technology, the functions and performance of metal sheet perforated machine are also constantly improving, enabling it to meet the increasingly diverse market needs. In this article, BRUTE STEEL SLITTER will discuss with you the uses, technical characteristics and importance of perforated metal machine in various industries. |

|

The core function of perforated metal machine is to process metal coils into holes of specific shapes and sizes through a punching process. These holes play an important role in the use of metal materials, and their specific uses include:

(1) Breathability and heat dissipation

In many applications, metal sheet perforated machine can be used to manufacture components with breathability or heat dissipation functions. For example, in the construction industry, metal punching materials are often used for exterior wall decoration and ventilation systems. Through punching, the metal surface can achieve better air circulation, thereby improving the comfort and energy efficiency inside the building.

(2) Lightweight design

In the automotive and aerospace fields, perforated metal machines are used to reduce the weight of materials. By punching holes in metal parts, the weight of the material can be effectively reduced while maintaining its strength and rigidity. This lightweight design not only improves fuel efficiency, but also reduces emissions, which is in line with modern environmental protection trends.

(3) Filtration and separation

Metal sheet perforated machines are also widely used in the manufacture of filtration and separation equipment. The perforated metal sheet can be used in liquid or gas filters to help remove impurities, ensure the purity of the fluid and the normal operation of the system. The aperture and hole type of the punching can be customized according to specific filtration needs.

(4) Decoration and beauty

In home appliances and electronic equipment, perforated metal machines can be used to manufacture metal casings with decorative effects. Through different punching designs, the beauty and market competitiveness of the product can be increased. In addition, the punching design can also enhance the brand recognition of the product and attract the attention of consumers.

(5) Structural support

Metal punching materials are often used in the manufacture of structural supports, such as brackets, frames and bases. Punching can reduce the weight of the material while maintaining its load-bearing capacity. This application is particularly important in construction and industrial equipment, which can effectively improve the stability and safety of the structure.

BRUTE STEEL SLITTER metal sheet perforated machine has a place in the market with its high efficiency, precision and flexibility. The following are its main technical features:

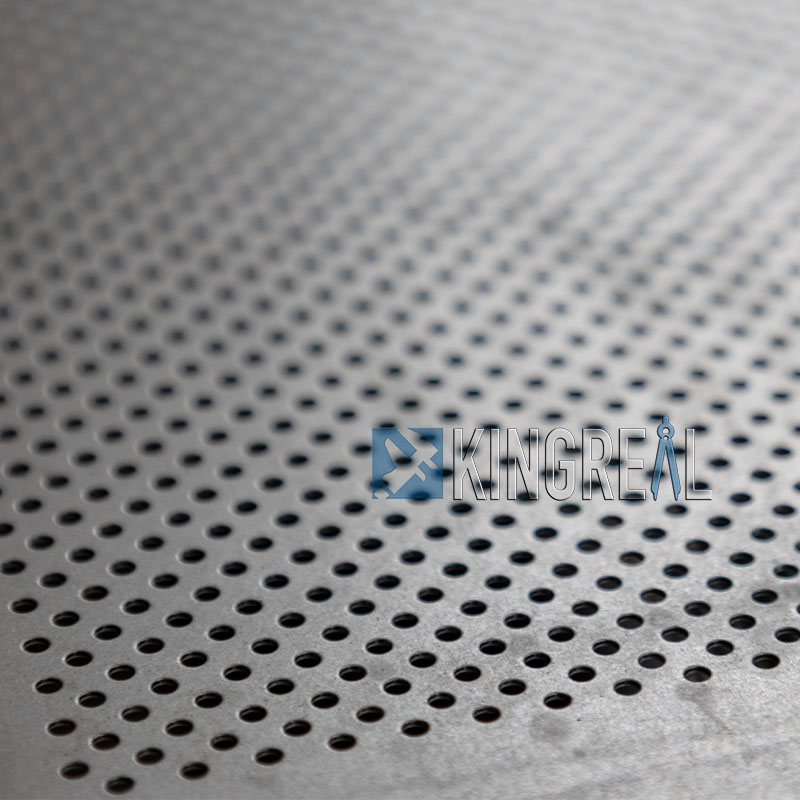

(1) Diverse aperture selection

BRUTE STEEL SLITTER sheet metal perforation machine provides a variety of punching services with different apertures to meet the diverse needs of customers. Common apertures such as 1.8mm and 2.5mm are widely used in the production of various products. However, BRUTE STEEL SLITTER perforated metal machine is not limited to these common apertures. After research and development by engineers, it can also punch out smaller micro holes. For example, the 1.0mm aperture die customized for Greek customers and the 1.5mm aperture die customized for Moroccan customers fully demonstrate the advantages of BRUTE STEEL SLITTER in micro hole punching technology. Punching dies are difficult to manufacture, especially for small-diameter punching. BRUTE STEEL SLITTER team of engineers has extensive experience in designing high-strength, durable punching dies to ensure stability and long service life under high-intensity production conditions. The advantage of this high-strength die is that it can reduce die wear and replacement frequency, reducing operating costs.

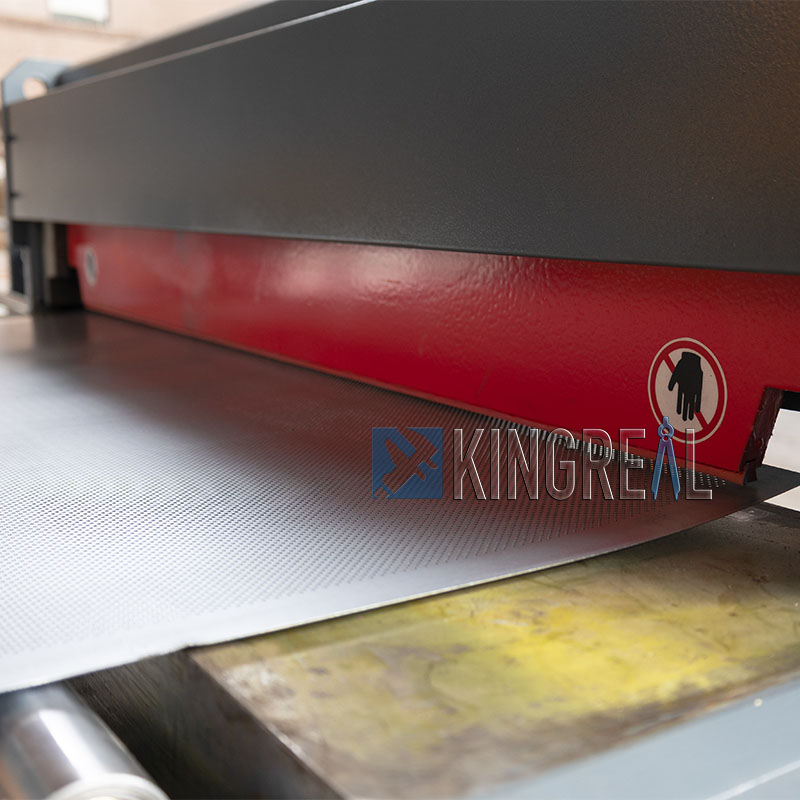

(2) High-precision punching

The BRUTE STEEL SLITTER sheet metal perforation machine is equipped with an advanced control system that can achieve high-precision punching processing. Through computer numerical control technology, the error of punching is controlled within a very small range, ensuring that the hole type and size of each product can meet customer requirements. This high-precision processing capability makes BRUTE STEEL SLITTER stand out in the technical competition.

(3) Efficient production

The BRUTE STEEL SLITTER metal sheet perforated machine has extremely high production efficiency and can process a large amount of metal coils in a short time. Its high degree of automation reduces manual intervention and improves production efficiency. This is especially important for customers who need large-scale production, which can effectively reduce production costs.

(4) Customized service

BRUTE STEEL SLITTER provides comprehensive customized services, designing and manufacturing punching dies of different specifications according to the specific needs of customers. This flexibility allows customers to quickly adjust production plans according to market demand to meet the needs of different industries.

|

|

|

The wide application of metal sheet perforated machine makes it an important equipment in many industries. The following are specific application cases of perforated metal machine in different fields:

(1) Construction industry

In the construction industry, metal sheet perforated machine is used to manufacture building materials such as ventilation grilles, metal curtain walls and partitions. Through punching, the air permeability and aesthetics of the building can be improved to meet the needs of modern architectural design. In addition, metal punching materials can also be used in components such as balcony railings and stair treads to enhance the safety and functionality of the structure.

(2) Automobile manufacturing

The demand for perforated metal machine in the automotive industry is mainly reflected in the manufacture of body structures, chassis and interior parts. Through punching, automobile manufacturers are able to achieve lightweight design and improve the fuel efficiency and performance of vehicles. For example, perforated metal sheets can be used for parts such as car doors and roofs, which not only reduces weight but also maintains good strength and safety.

(3) Electronic equipment

In the manufacture of electronic equipment, metal sheet perforated machines are used to manufacture components such as housings, heat sinks and brackets. The punching design can improve the heat dissipation efficiency and ensure the stability of electronic equipment during operation. At the same time, the appearance design of the punching can also enhance the aesthetics of the product and increase market competitiveness.

|

|

|

(4) Home appliance industry

Perforated metal machines are widely used in the home appliance industry to manufacture housings and internal brackets for products such as refrigerators, washing machines and air conditioners. Through precise punching processing, home appliance manufacturers can improve the heat dissipation performance of products and ensure the normal operation of electrical equipment. In addition, the punching design also adds a sense of fashion to the appearance of home appliance products.

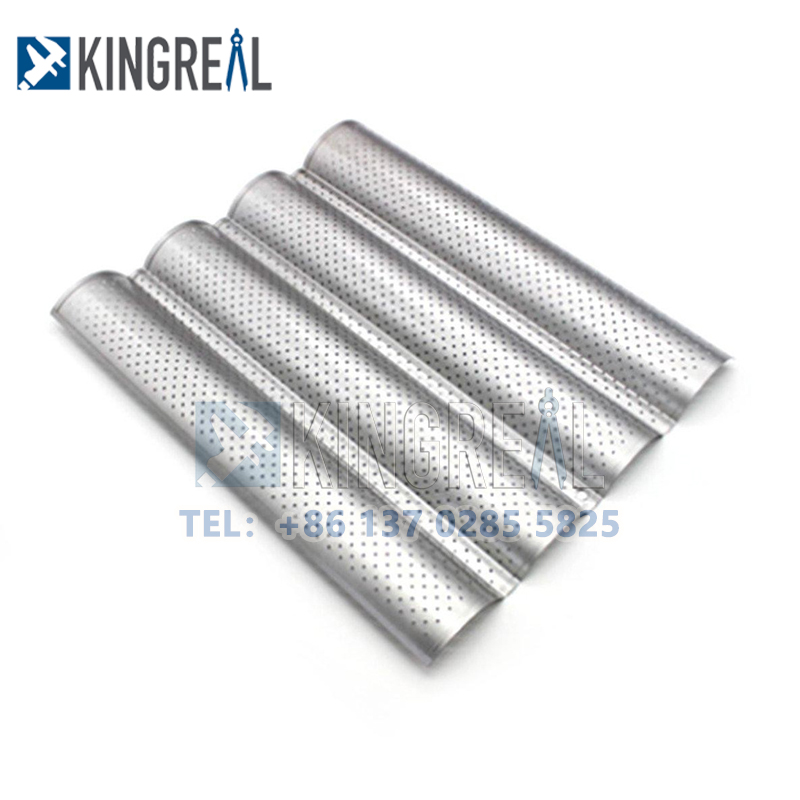

(5) Filtering equipment

The manufacture of filtering equipment is one of the important application areas of metal sheet perforated machines. The punched metal sheets can be used for liquid and gas filters to ensure the normal operation of the system and the purity of the fluid. According to different filtering needs, perforated metal machines can provide punching services with different apertures and hole types to meet industry standards and customer specific requirements.

(6) Transportation

In the field of transportation, sheet metal perforation machine is used to make road signs, traffic lights and other signs. Through punching, clear logos and patterns can be made on metal materials to improve traffic safety. At the same time, the structural design of the punching can also enhance the durability and wind resistance of the logo.